Products

VLD class 2.1

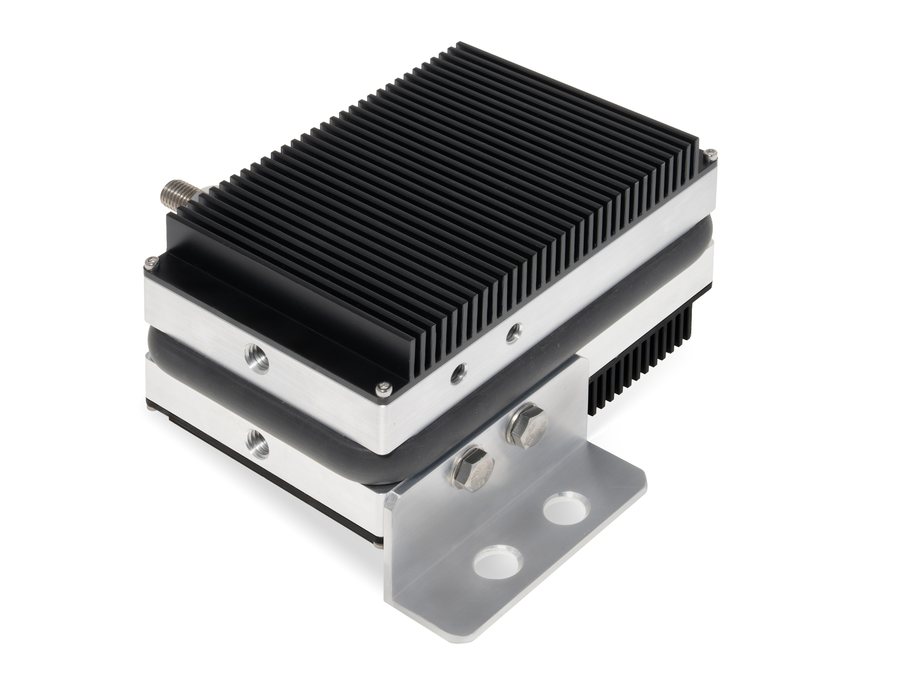

The VLD class 2.1 from Rudolf Waechter is a unipolar voltage limiter of the VLD-O (or VLD-O+F) type designed especially for DC traction. Its exceptional repeatable electric parameters predetermine it for all types of DC railways, including modern ones with powerful substations and high operating currents. The VLD class 2.1 consists of a set of high-energy varistors connected in parallel with one electronically controlled power thyristor. The task of the A2 varistors is to protect the surrounding and the internal semiconductors of the VLD from pulse voltage (especially lightning strikes, etc.) with a short delay the thyristor then reacts to the impermissible touch voltage, which, by switching on, establishes an equipotential connection of the track with the ground and thus protects passengers (and the varistors from destruction). The reaction of the thyristor is set during assembling the control electronics and is two-stage. If the voltage potential at the VLD terminals exceeds the voltage limit UTi, the thyristor typically switches with a delay of 1ms. If the voltage potential is lower than UTi but at the same time higher than UTn, the thyristor response is typically 10ms. However, the voltage and time switching levels can be set to other values according to the customer’s needs upon agreement during production (of course within the limits set by the EN 50122-1 standard). The VLD class 2.1 anode is marked with a “+” sign, which is connected to the rail at the traction, where the OCL is connected to the positive pole of the substation. The VLD body is manufactured by precise CNC milling in order to achieve exceptional electrical parameters. A special aluminium alloy is used for the VLD body, which is resistant to acidic and salty atmospheres. The voltage limiter is also equipped with sensor that monitor the maximum operating temperature of the thyristor and can be supplemented with a radio module that is capable of remotely indicating device overload.

The main function of the VLD-O is to protect passengers, staff and technology from non-permissible touch voltage that may occur on the return conductor (rail) during normal train operation, especially at greater distances from substations (the reason is the higher voltage drop on the long return conductor). The use of class 2.1 has certain limitations, or rather, certain conditions must be met for its use. In particular, it must be known that long-term voltage potentials of opposite polarity cannot occur on the protected rail, which can happen, for example, when using recuperation, in the event of a short circuit on a long OCL and a return conductor loop with a large reactance, etc.). If class 2.1 is used where the conditions are not met, irreversible damage to the VLD will occur sooner or later. In the event of opposite polarity of the voltage on the VLD, the varistors are not protected by the thyristor switching and they will be destroyed. The safe solution in such a case is class 2.2 VLD. In certain cases, a suitable replacement for a class 2.1 VLD (in VLD-F mode) may be a safe class 2.2 VLD with an asymmetrical switching voltage (usually a combination of UTn = 120 / 350 V), which we manufacture based on a special order. If you are unsure about the suitability of using class 2.1, please contact our technical support. We will together consider the situation and recommend a suitable solution.

VLD class 2.2

Voltage limiting device class 1 with remote indication of status

- Voltage limiting device for railways (type VLD-F) according EN 50526-2 for fast protection of personnel, passengers and equipment even during OCL failure

- Integrated patented VLD-status sensor with remote wireless status signalling for early VLD failure warning

- Stray current (infrastructure corrosion) minimizing through early detection and replacement of damaged VLD

- Ultra-low power consumption of electronics (> 10 years battery lifetime) when status transmitted once a day = no external power supply needed

- No more expensive physical check needed (= OPEX savings)

- For both DC and AC traction systems equipotential bonding in case of break, short-circuit or earth fault of OCL

- Lightning surge protector integrated

Voltage limiting device class 2.1 with high recoverable load

- Voltage limiting device for railways (type VLD-O+F) according to EN 50526-2 for fast protection of personnel, passengers and equipment during train operation and even OCL failure

- Extremely high recoverable load for application as repeatable VLD-F or cheap replacement of VLD class 4

• 25 kA @ 50 ms

• 3 kA @ 30 sec - Industrial design for maximum performance

- Optional patented VLD-O status sensor with remote wireless status signalling for early VLD failure warning for stray current (infrastructure corrosion) minimizing

- No external power supply needed

- For DC traction systems equipotential bonding in case of operational excessive touch voltage, short-circuit or earth fault of OCL

- Lightning surge protector A2 integrated

- HS = with heatsinks; WS = with wireless sensor

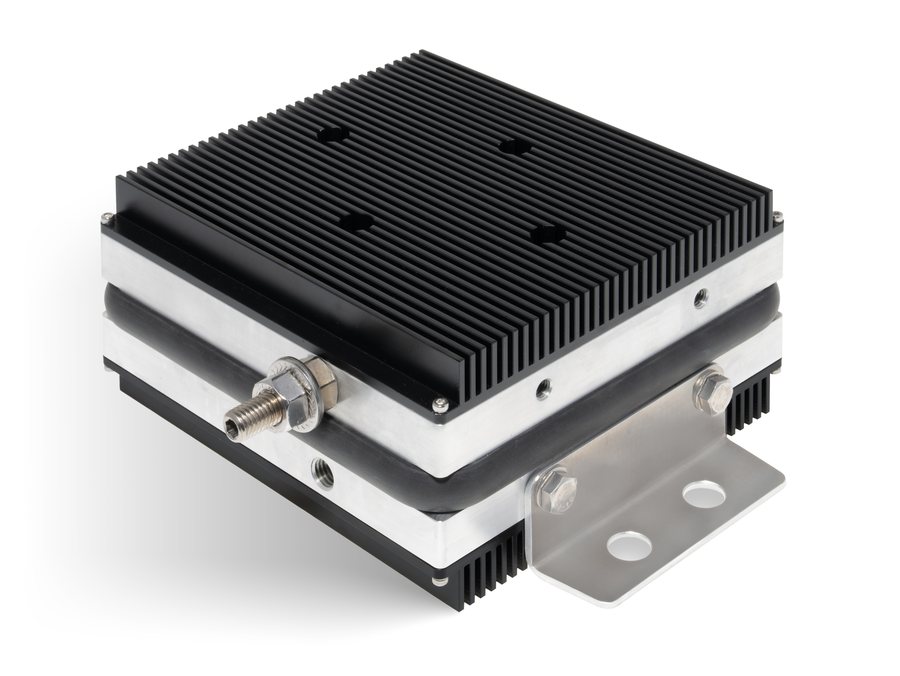

Voltage limiting device class 2.2 with high recoverable load

- Voltage limiting device for railways (type VLD-O+F) according to EN 50526-2 for fast protection of personnel, passengers and equipment during train operation and even OCL failure

- Extremely high recoverable load for application as repeatable VLD-F or cheap replacement of VLD class 4

• 25 kA @ 50 ms

• 3 kA @ 30 sec - Industrial design for maximum performance

- Optional patented VLD-status sensor with remote wireless status signalling for early VLD failure warning for stray current (infrastructure corrosion) minimizing

- No external power supply needed

- For both DC and AC traction systems equipotential bonding in case of operational excessive touch voltage, short-circuit or earth fault of OCL

- Lightning surge protector A2 integrated

- HS = with heatsinks; WS = with wireless sensor